THE WILLESDEN WAY

Part One

It was 1924 and I was looking for a job. Having left school at the end of the summer term and written letters and attended interviews without success, it seemed doubtful whether I should ever find employment. I was at some disadvantage, for not only had I gained no school qualifications but when asked what I wanted to do, all I could suggest was that I wanted to make things. Preferably artistic things. In 1923 the trend was away from hand craft towards mass production.

It was therefore a relief, at the end of September to learn that I was to go with my father for an interview to an engineering firm at Willesden Junction. Here it was hoped that I should be accepted for a five years apprenticeship. It would not involve much art, but at least it would be manual.

I was sure that none of my late school friends had expected to go into engineering. They were going into the family business or into a bank or an oil company. There was a certain stigma about wearing overalls and getting one’s hands dirty. However, an apprenticeship would mean that my future would be settled for the next five years, and that to a youth of sixteen was forever!

The next morning we set out from Cricklewood and caught the tram at the request stop in Chichele Road. I sat absently looking at the rows of travellers on the bench seat opposite and felt as I had done when on my way to hospital to have my tonsils removed. Would it be difficult? What would they expect me to be able to do?

Through the open doorway I could see the driver standing at his controls, swinging the levers back and forth to control the speed. The scent of dust and horse manure drifted through the compartment; this changing to the smell of hot iron as the brakes were applied down a long gradient. The tram swayed and ground its way up the hill past Willesden Green station, where the last horse cab stood waiting for a fare. Down the hill, through Willesden and Harlesden, round by the Jubilee clock and into the Harrow Road. From now on the journey was all new to me. I had never ventured down the Harrow Road. Finally we jerked to a halt at the College Arms Hotel on the corner of Scrubs Lane and had to do the rest of the journey on foot. Down Scrubs Lane for about a quarter of a mile and turn right into Hythe Road. Under the railway bridge and past the BNV motor works. Now along beside the high brick wall on the left until we came to a gateway in the wall. This was it. Baker Perkins Limited.

A man in a cloth cap, standing by his wooden hut, enquired our business and directed us to the right, across the factory yard. In the centre of the yard was a new block of offices which appeared to be finished but unoccupied. Beyond this we came to a heavy wooden door in the wall of a row of two-storey buildings forming the western boundary of the site. We entered, climbed a wooden staircase and so to the office of the chief draughtsman.

Mr Prescott was a short sturdy little man who seemed to be very busy and always anxious to hurry on. However, he was pleasant and after a few questions invited me to show him a drawing I had made. It was a copy of a gun sight drawn from an artillery hand-book which my father had brought home from the war. I’m afraid I lost marks when I had to admit that I had no idea how it worked. I had only copied it.

With that we were directed to see the works manager. He would arrange the details of the apprenticeship and draw up the necessary papers.

Back towards the main gate, to a row of buildings on the opposite side of the cobbled yard. These were obviously the commercial offices with a more imposing entrance. From a small hall we went up to the first floor and along a passage past a succession of offices. It was all dark brown paint and varnish. Dark brown linoleum on the floor and a pervading smell of old wood and carbolic soap.

Mr Binns, the works manager, was expecting us and had all the papers ready for discussion. He was a tall man dressed in a light grey three piece suit, a stiff wing collar and broad knot tie. He was very attentive and for some reason reminded me of a non-conformist minister. He laughed very readily and I decided that I should like him. It appeared that I was too old, being already sixteen, to start an apprenticeship as the five years had to be completed at the age of twenty-one. This was overcome by back dating my entry, so that according to my indentures I had started before I had in fact left school. The next problem was that there was no immediate vacancy for me in the works and I should have to wait six or nine months before my training could begin. This was solved by making a job for me as a Drawing Office Assistant, and the time thus employed was to count as part of the contract. When everything had been satisfactorily agreed, Miss McLellan, the secretary, was called in to collect the papers and insert the relevant dates and details.

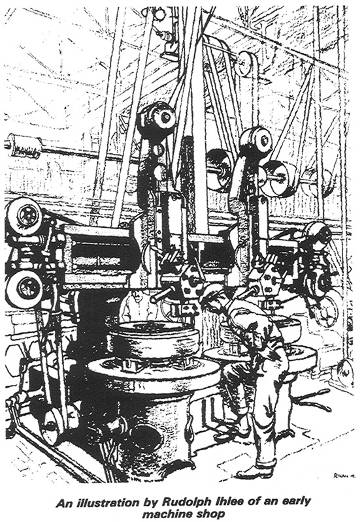

To fill in the time while this was being done, Mr Binns suggested that we might like to visit he Works. He led the way from his office along the corridor to a swing door at the far end. As he opened the door I was deafened by the mighty roar of the factory. There were shafts and pulleys flying round in all directions and some of the belting seemed to be very close above our heads. I had never been in a factory before and had never imagined such a shattering noise.

We had entered the factory on a wooden gallery at first floor level and made our way between men and machines to the end of the building. Mr Binns spoke to a very surly man sitting on a stool outside a dark little office and then took us to inspect a biscuit moulding roll and some cutters. The clean cut impressions of familiar biscuit shapes in gleaming brass looked beautiful. Yes, that sort of thing would be very nice to make. The surly foreman of this department, the cutter shop, was Old Man Hole, whose son Bill was in the drawing office.

How much more of the factory we visited I cannot remember, but it was a great relief to return through the swing doors into the office corridor.

On our return, the papers were completed and ready for signing. I have them before me as I write. There is my spidery signature agreeing to start work for a wage in the first year of 2.04 pence per hour. Though this may be considered a rather small reward, it must be remembered that not long before this, my father would have had to pay for my instruction in the mysteries of engineering. The die was cast and I returned home to prepare for my new life with instructions to report next morning at 8.45 am for work in the Drawing Office.

There was no question as to what I should wear for the office as I only possessed one suit with long trousers. That was my school uniform of black jacket, waistcoat and striped trousers. With this I wore a white shirt with a soft detachable collar. The tiepin pinned under the knot of the tie, to hold down the points of the collar; the fashion of the day. I had to go without a hat as I could not very well wear my school cap.

Arriving at the office, I reported to Mr Prescott and was taken to the Tracings Store. This was a large room lined on three sides with wooden drawers. The fixtures stood about six feet high with wooden drawers.

The keeper of the Tracings Store, for whom I would be working, was Tom Flux. He was a very tolerant man, possessed of endless patience and did a lot to ease my transition from school to work. He was a great conversationalist and was always discussing the affairs of the day with various draughtsmen who came in from the main office for a quiet chat.

He showed me round the room and explained how the drawings were numbered and filed. Each trade had its own letter; thus “A” was for flour, “B” was for biscuit, “C” was for chocolate and so on. The next letter described the type of machine, so that “BA” indicated a biscuit cutting machine and “CQ” was for the chocolate enrober. The parts drawn up to make one of the machines were given consecutive numbers. My job was to sort out the tracings brought in from the Drawing Office and file them away in their appropriate places. The draughtsmen helped themselves to the drawings they required for reference and left it to me to put them away again.

Having described all this, it was suggested that I should meet the draughtsmen as another of my duties would be to fetch the office tea.

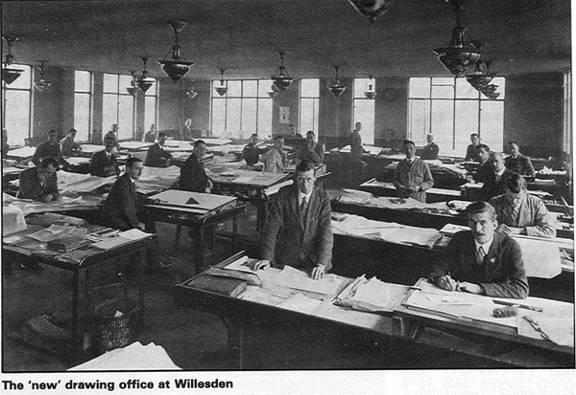

Mr Flux took me across the landing at the head of the stairs past Mr Ralph Baker’s and Mr Prescott’s offices on the right and the print room on the left, out into the Drawing Office. This was another large room with a north light roof. The draughtsmen’s tables were arranged in rows backing on to Mr Prescott’s office. Each table had a large drawing board supported on wooden wedges and supplied with a mahogany tee square. Additional space was provided for reference drawings.

On the back row was Bert Williams. Next to him, Claude Dumbleton, Bill Robertson and Jack Bunce. In the next row sat Basil Worthy, Mr Dickenson and Frank Pulham. Beside Frank there was a bookcase where the standards books and catalogues were kept. Frank was the librarian and a source of information for the whole office.

Among the men to whom I was introduced were Mr Honey, Edwin Wingrave, Monty Pinion, Bill Brewer, Pop Lander, Jack Hart, Bill Hawden, Cushing and Harry Birchler. Harry was a Swiss who seemed to spend most of his time in the works.

Down one side of the office there was a glass partition dividing off a narrow section, and here, sitting at their desks were Rusty Sands, the manager of the Drawing Office, and Mr Whalley who was in charge of Patents.

Out of this narrow section, a flight of stairs led up to an attic. I never did go up there but it led to the dark room for Percy Guscott, the photographer and Alec, his assistant.

After this general survey, we returned towards the Tracings Store calling at the print room on the way. The print room was run single-handed by George Jordan. He wore a black suit with a watch chain looped across his waistcoat and always worked with his jacket off and his sleeves rolled up. George did not smoke; I don’t think he would have had time to light a cigarette, so he chewed tobacco. This made his speech somewhat indistinct but if you did make out what he was saying, it was usually to complain about the impossibility of doing so much work. He never stopped to chat and just managed to keep pace with the demand for prints.

His equipment was simple. One printing machine consisted of a large glass cylinder standing on one end with a carbon arc lamp mechanically driven up and down inside. The procedure was to wrap the tracing and the print paper round the outside of the cylinder and secure them with a canvas wrap which was strapped tightly to hold everything flat. The lamp was then switched on and left for the required printing time. The other machine was more modern. Here the tracing and paper were fed horizontally and the lamp was driven to and fro. All the prints were blue prints; that is to say that the ground of the paper was blue and the lines white. After printing, each sheet had to be washed in a shallow zinc-lined tank, dried off with a rubber squeegee and hung up in the drying cabinet. The cabinet was a galvanised box, electrically heated and it had lines stretched across the top inside, to which the prints were clipped with wooden clothes pegs. When it is considered that George made all the prints for the Works as well as for office use, there is little wonder that he felt hard pressed.

George had lived all his life in Harrow and was very proud of the fact that he was on the local council. It was said that, when a boy, he had helped in a newsagents on Harrow Hill and that he had had trouble with the public school boys. They delighted in tipping the news placards, arranged in front of the shop, down on to the pavement as they went past. To discourage this practice, George had dashed out of the shop and caught one of the boys in the act. He gave him a smart clout round the head and later discovered that the boy was Winston Churchill.

I spent the morning sorting tracings. Some were on paper and others on blue linen. Some were drawn in pencil, but most, even on tracing paper were in ink. There were the smallest, twelve inches by nine, then those eighteen by twelve and after that the sizes had funny names: Imperial, Double Elephant and Antiquarian. Every draughtsman had his own distinctive style of lettering. Some were very flowing and artistic.

While I was thus engaged, Tom Flux would sit at his table and perform the ritual of rolling a cigarette. He was a great roller of homemade cigarettes. The Rizla paper, the St Julian tin of loose tobacco, the careful rolling to and fro before licking the gummed edge and the final roll up. Next the pinching off of the surplus tobacco from the ends and returning the precious fragments to the tin before lighting up. I always thought the end result most disappointing. The cigarettes were thin and the ends collapsed: not at all like the bought variety. They would never keep alight and as the stump got shorter with repeated lighting, it became necessary to turn the head to one side to avoid burning one’s nose!

Then he would start writing up one of the big leather bound ledgers.

When a draughtsman started work on a new machine, Tom would decide the number and letters to give it and make an entry with pen and ink in his regular flowing hand.

Bill Hawden came in and started giving a graphic account of the football match last Saturday at Wembley. Bill was in the St John Ambulance and was usually on duty at sporting events. Mr Carpenter or Carp, as he was known in the office, joined the group and the detailed discussion was in full swing when it was “Eye up!” and Rusty Sands came in. There was an immediate switch in the conversation to some fictitious drawing numbers and Carp silently melted away. Of course, Rusty knew what was going on but he was doing his job and keeping the men at work.

At ten thirty I had to take orders for morning tea. First, Mr Dumbleton. He just wanted a cup; that was two-pence. Then Basil Worthy; he wanted a pot of tea for one. This meant a very small tea pot and a minute milk jug giving two cups of tea. That was four-pence. Someone else wanted a cup of tea and biscuits, three-pence; and so it went on. When my order was completed I went over to the Canteen in the yard opposite the new offices. The Canteen was a wooden structure rather like a cricket pavilion, divided into three sections. The Works Canteen on one side and the Staff room on the other with the kitchens in between. I imagined that it had been built during the war for the munitions workers. I went up the steps to the works section and gave my order over the counter. Mr Foster was in charge. He had a hard face and looked as though he would stand no nonsense. This I learned later was misleading as he was very kind to me.

My order completed I carried the heavy white enamelled tray back to the office door in the wall. The trick was to lodge the edge of the tray in a groove in the brickwork while turning the door knob with the free hand. I only once failed in this manoeuvre and dropped the lot. It was then that I learned that Mr Foster had a heart of gold. He just gave me a lecture but did not ask me to pay for the breakages. I shudder to think how many weeks it would have taken me to pay for that accident.

Part Two

As the weeks went by, I learned the pecking order in the Drawing Office. Dum even in those days seemed to be most important, leading a team of Basil Worthy and Dickinson, Jack Bunce was highly esteemed. He was a clever all round draughtsman with a flare for design.

A great deal was hoped for from him and it was therefore a terrible loss when he died quite suddenly. I think he “caught the ‘flu’.” There were a lot of deaths from influenza about that time. Jack Hart, I was told was a “Whitworth Exhibitioner”, a very important qualification. He had been trained in the railway workshops and was to some extent responsible for the very substantial machines for which Baker Perkins was noted.

Ben Williams drew up factory plans showing our machines arranged in the customers’ premises. He claimed to be a member of a theatrical family and certainly with his long hair and gaunt appearance it could well have been true. He often gave a comic turn for the delight of the office. He used to go up to the College Hotel in the lunch hour with Dum and Robbo, as Dum always liked to have a clown in his party when he went to the pub.

The biscuit cutting machines were drawn up by a man called Swaffield, “late of the Guards” he was never slow to tell us. He was a tall chap and adopted a swaggering gait as though he had just left his horse outside. I don’t think he was particularly bright and five years later he had left Baker Perkins.

Edwin Wingrave had been brought up from the Carpenters Shop to draw up the wooden Mogul. This was a starch printing machine used to make indentations in trays of starch which were subsequently filled with jelly. When the trays of jellies had been dried in the “Hot Room” they were returned to the machine to be emptied. The starch was sifted, the jellies separated and the whole cycle repeated. The frames of this machine were of stout planed timber, shellac varnished, carrying the conveyor chains which were of the malleable iron interlocking type made by Bagshawe.

“Pop” Lander did the enrobers. He was called “Pop” to distinguish him from his son “Jeff” who worked in the Cutter Shop office. “Pop” Lander was a bright active little man who gave the impression that he was right on top of his job. Whether this was true I could not judge, but Jack Hart later took over the enrobers from him.

Bill Brewer, I remember for his advice on household decorating. I don’t know which machine he worked on. He was always discussing the best paint to use or how to get an electric cable through the ceiling to the floor above.

Mr Honey was another office character. He always had something to sell. He had acquired a book of recipes for making shoe polish or toothpaste and all manner of useful materials at a very low cost. He would make up these bargain lines and put them into tins which he hawked round the office. One day he had a cheap line in Briar Pipes. I never heard what happened to him but I am sure that his future was not in a drawing office.

Last of all, I think, was poor Monty Pinnion. He had very broad double-jointed thumbs which Claude always claimed had been developed by constantly pressing drawing pins into his drawing board. He was not a very great draughtsman and I learned later that he had left to take up a job reading gas meters.

The draughtsmen were all individualists, prepared to design and draw up any machine a customer wanted, under the direction of Mr Ralph Baker or Harold Prescott. It was common practice for the draughtsmen to go into the Works and discuss a job with one or other of the foremen; giving close co-operation between the Works and the Drawing Office.

As the darker days of winter approached I would go into the Drawing Office on my errands and watch the men working at their boards. If a man were short and it was necessary for him to work at the top of his board, he would stand on his foot stool and literally lie on his board, like a snooker player, in order to reach the top. Each board had its own electric lamp with its coolie hat type shade. The lamp was suspended from a chain attached over a roller in the rafters to an egg-shaped lacquered brass container. This ornate piece of furniture was loaded with lead shot to counterbalance the lamp so that the light could be raised or lowered at will. Of course, if you needed to move it sideways then you had to use a piece of string and a drawing pin. One could at least get the light right down on the job and the later shadowless lighting used in the new offices was never felt to be so efficient.

Mr Frank Pulham peered over his glasses as I walked round. He was a kindly man always trying to be helpful, going to endless trouble finding information for everyone. He was responsible for the Standards Books. These were books of drawings of spur wheels and pulleys for which patterns existed and he was always trying to get the men to use these rather than draw up new items. On top of his bookcase was the oilstone. This was used to sharpen ruling pens and penknives which were part of every draughtsman’s equipment. There also stood the big bottle of drawing ink from which the men took their supplies.

The only notable event I ever heart about Frank was that some years previously he had been on a walking tour in the Pyrenees. It had been the highlight of his life and he never tired of telling us about it.

Inevitably, the endless task of putting drawings away in the cabinets resulted in my filing one in the wrong place. The draughtsman would complain that he could not find a particular drawing and arguments would follow as to where it might be. To me, it was an absolute disaster, for where, among those thousands of drawings, should I look? I searched without the slightest hope that I should ever find it. In the end, Tom Flux would come to the rescue and, by some uncanny second sight, he seemed to follow my strange mental processes and track down the lost sheep. My relief was great indeed.

Sometimes when work was slack, I would look through some of the thousands of green patents journals which lined the shelves. I marvelled at the various seemingly useless inventions shown but occasionally came across some ingenious device which set me dreaming about the possibilities of machine design. I was however soon brought to reality by a great armful of assorted drawings returned for filing.

Being an office worker I was entitled to take my lunch in the Staff Canteen. The tables there were in groups, each for four people and complete with its own white table cloth. The menu though a bit restricted was good and plentiful and all cooked on the premises. Roast beef, cabbage and potatoes with rice pudding to follow for 9d (3½ pence). An alternative would be fish and chips followed by baked apples and custard. Of course a cup of coffee would be 2d. or 3d. extra; a luxury not to be indulged on ten shillings (50p) a week.

Standing against one wall of the canteen were frames of stage scenery which I understood had been painted by Jack Bunce for one of the firm’s operatic productions. They formed mural decorations for the white walls.

At Christmas time, the place was festooned with paper chains and a dance was once held there. The concrete floor was sprinkled with French chalk and a space cleared for dancing. I went along and thought it all very grand. I took my sister’s friend, in spite of the fact that I had never had a dancing lesson in my life. I don’t know what she thought of it and only hope that she got at least one decent dance.

About this time there was a lot of talk about moving over into the new offices; new equipment was being assembled and old records scrapped. One day Mr Prescott took me to an attic somewhere in the building to sort out some old drawings. It was a dismal place, lit by one naked bulb and on the floor was a great heap of large drawings. I was to look at each one and pick out anything which might be useful. I found this a bit puzzling because how was I to know what should be preserved? I think it was to ease his conscience, just in case he destroyed some sacred relic! I sat on the floor and faithfully turned every single drawing. Most of them were of brick ovens. They were drawn in ink on beautiful thick Whatman watercolour paper. Every brick was shown and all carefully painted red with steel tie bars picked out in Prussian blue. The oven fronts, which were of cast iron, were painted Payne’s grey. On reflection, I suppose that some of these were old Thompson drawings which we had inherited when we took over than company. They were chiefly peel ovens with an occasional Vienna type having the peeling pit in front. They were all beautifully finished drawings with artistic borders and flowing lettering, but all destined for the bonfire. Occasionally I came across drawings of single funnel steamers; beautifully picked out in full colour, though what they had to do with Baker Perkins I had no idea. I later heard a suggestion that at one time we had been interested in the disposal of refuse at sea. Nothing of this sort would surprise me, because we were engineers and therefore could undertake anything. Among this great heap of drawings I sometimes found clean sheets of this beautiful watercolour paper and these I put aside to take home. I might consign masterpieces to the flames but I could not bring myself to destroy good paper.

Plans were made for labourers to come in on moving day and shift all the drawings and equipment to the new offices. I think the move took place at Christmas time in 1924. We were going to have all new metal filing cabinets for the drawings. There was some firm called “Roneo” who made this sort of thing, but of course we were engineers and our plate shop could surely make a few drawers. The ones we made were not altogether a success. Some of the larger drawers when heavily loaded, slipped off their runners and jammed. Sometimes the drawer fronts pulled off and we often tore our hands on the jagged edges. Well, I expect “Roneo” had trouble with the first fixtures they made!

We went over to the new offices to see where the new tracings store was to be and found it all most impressive. Up the broad steps outside, through the swing doors into the entrance hall in the centre of the building. The time clock on the right with all the cards in neat racks. This was a new idea. We had not previously “clocked on”. In the centre of the far side of the hall was a lift with a staircase winding round it. A very tiny lift I remember, to hold four people with a squeeze. The Drawing Office was on the top floor and at the head of the stairs a corridor led left and right. To the left led past Rusty’s office into the D.O. To the right were Mr Ralph’s and Mr Prescott’s offices on one side with the tracings store on the other. The print room and the dark room were at the far end of the passage.

The offices were heated with a Perkins high pressure system which I think was subsequently altered to the more traditional arrangement. The lighting in the Drawing Office was of a very advanced shadowless type. This consisted of high powered electric lamps inside lacquered brass bowls. These reflected the light up to the ceiling and so down into the office. It did not prove a great success, however, as so much of the light was lost by the double reflection. It was also difficult to keep the bowls clean. They collected all the dust and were a temptation to mischievous draughtsmen who were known to flick an empty cigarette packet up into the bowls rather like a netball basket. The heating system sometimes made the office very hot and a thermostat fitted outside Rusty’s office failed to control it. Rusty, who smoked a pipe continually and never took it out of his mouth, would complain that he had no faith in these new fangled gadgets. Poor Rusty, no one respected him very much. He complained about the waste of tracing paper. We had no printed sheets and the draughtsmen just cut off what they required from the roll. He complained about the misuse of all the office equipment. All he wanted was a quiet life. He had been with the firm for many years and told a tale of his experiences when working in the Argentine with our salesman Bruce Hay. Conditions were lawless in those days and he had slept with a revolver under his pillow.

Part Three

The great day came at last and we arrived to take up our places in the new office block. All the old drawing boards had been moved over, but as far as possible all new equipment such as coat lockers were made of steel. I have no doubt that the first insurance company had been horrified at the conditions in the old office. Only one exit down a wooden staircase to the outside yard. Wooden floors, roof and fixtures. To say nothing of the pipes of paper and the photographic equipment up in the attic!

We soon settled into our new environment. Everything was most luxurious. Lavatories on every floor, instead of having to walk over to the canteen. Red terrazzo floors and green paint. It was all voted a great improvement.

We took on a new man about this time, named Porter. He was a very sociable fellow fond of practical jokes. He used to tip the wooden wedges under a colleague’s board so that as soon as the draughtsman rested his arms on it, the whole thing collapsed with a bang. He was a nice draughtsman with a good style of lettering. No one knew much about him and he did not say much about his previous employment. He worked well for a time and then would have a day or two off sick. Gradually these days off became more frequent and Rusty was sent round to his home to find out how he was getting on. It was then confirmed, as some of the men had already guessed. Mr Porter was an alcoholic. In those days this was not recognised as an illness but a wicked form of self indulgence. So Mr Porter had to go.

Mr Prescott called me into his office one day to meet a Mr George Wilson and I was asked whether I had done chemistry at school. This came as a bit of a shock. I had to explain that I had but unfortunately this was not one of my best subjects. I had visions of problems with involved chemical formulae. However, I was soon put as ease because all they wanted me to do was to use a chemical balance. I went with Mr Wilson to a disused building close to the works canteen and was given a soft brush, some fine sieves, a balance and various samples of icing sugar.

We made at that time, a sugar disintegrator, which broke up granulated sugar into very fine powder for chocolate making. My job was to sift the sugar and determine the quantities of various grades in a given sample. It was tedious work and the fine sugar drifted about the room, so that there was always an alarming discrepancy between the original sample and the various weights which I recorded. It was a lonely task and I was glad to get back into the office again.

I had a similar job on another occasion when we were trying to determine the best lubricant to use for the long linked roller chains used in both biscuit and bread ovens. This time I went with Mr Wilson to a big wooden hut just inside the factory gate. It was fitted out as a complete chemical laboratory, which I learned later had been equipped for Mr Ronald Head, our adviser on chocolate making. My job was to put weighed samples of oil into a furnace and keep them at a constant oven temperature for very long periods. Observations had to be made of the condition of the samples from time to time, and the final weight recorded at the end of the test. I tested Duckhams, Adcol, Wakefields oils and other brands but most of it finished up as a sticky tar.

It may be considered surprising that we did not ask the oil companies to carry out these tests but in those days it was more usual to solve one’s own problems in the factory. In Any case, I think it was finally decided to use a mixture of graphite and water on the oven chains. This was another lonely job and I whiled away the time examining everything I could find under a powerful microscope in the laboratory.

My work, filing drawings in the new office was just the same, apart from the fact that I no longer had to fetch the tea. By now, I had, of course, enrolled for evening classes as this was all part of the apprenticeship training. I had to attend the Paddington Technical School for three evenings a week, with a view to obtaining a National Certificate. I had never heard of this examination and assumed that it was some sort of test devised by the school. I did not appreciate its importance and wished later that I had worked harder to achieve this qualification.

At last, I received instructions to report to the machine shop manager to start my works training. When the news got round that I was leaving the office, the draughtsmen presented me with a collection of tools as a parting gift. A twelve inch steel rule, callipers, a square, a scriber and other useful items. I had had no idea that a collection was in progress on my behalf and I was most impressed with this valuable present. I still have the callipers and the twelve inch rule. These are all that have survived after fifty years.

My father had bought an old bicycle from Tom Flux so that I could cycle to work and be independent of the trams. I should now have to start work at 7.30 am six days a week. I bought myself an alarm clock, a boiler suit and some cheap working clothes so I was all equipped for the new job. One last round of the office to thank everyone and say goodbye, and so home to prepare for an early start on the following Monday morning.

Mr Borham was the machine shop manager and he decided that my training should start on the Milling Section. He took me to an area under one of the wooden galleries and introduced me to Jim Record the charge hand. He was a slim young man wearing a flat cap and a brown warehouseman’s coat. He was very alert and busy on the section but he never seemed to get dirty like the rest of us.

I was shown to a vertical machine at the end of the section, close to the big sliding doors that opened into the factory yard. A very draughty position. Here he gave me a short description of the machine. The long wooden lever that guided the belt from the loose to the fast pulley and started the machine. This hand wheel moved the table in this direction and so on. While I was trying to take all this in, he shot off down the section telling me that he would be back in a minute and that I was not to move away from my machine.

Beside me there was a large cast iron column; one of a row which supported the gallery above. On this I found a convenient loop of wire on which to hang my coat and surveyed my new surroundings. At the foot of the column stood my tool cabinet. It had long since lost its door and now consisted of a top and one shelf. It was battered and chipped and the whole thing inside and out was covered with a thick layer of black grease and cast iron dust. On this I unpacked my new boiler suit. As I stood waiting for Jim to return I felt very conspicuous in my new uniform. The milling machines were arranged in a double row with a gangway down the middle. They were all belt driven from one powerful electric motor positioned halfway down the section. This drove the line shafting suspended from the wooden gallery above. It was a mass of pulleys and flying belts. In addition to the milling machines, there were two centre lathes on the other side of my column also driven from the common line shaft.

I turned again to my machine and decided that it was very old. The surface of the table had been accidentally cut at various times and one section of its slotted surface had been patched with steel strips. I gingerly turned some of the hand wheels to see what happened but dare not pull the wooden lever which I knew would start it up.

Jim came back with some cast iron bearing brackets which he explained were to be machined across the base. He turned to my tool cabinet which was of course empty apart from a worn out twelve inch flat file and one or two nuts and bolts of useless proportions. He sorted through these and then went across to my neighbour to get some clamps and bolts to set up the first casting on the table. “You want to get yourself some of these” he said, referring to the clamps and bolts but without suggesting where I might go for these. Next, he went to the tool store and came back with a cutter and three or four brass “checks”. These were about the size and shape of a 50 pence piece and stamped with my number, 30. They were to be used in exchange for cutters at the tool store. The machine was started up and he milled a flat surface on the first casting. “Now do the others in the same way” he said and left me to get on with it. I soon found that not only was the table badly scarred, but that there was considerable backlash in the screws that wound the table along. It was necessary to always arrange that the table was being pressed towards the rotation of the cutter. If one failed to do this, the cutter snatched the work and pulled the table along leaving all sorts of marks on the machined surface.

It was all very interesting, but by the time I had cycled home after standing all day I was tired. My hands and fingernails were black with cast iron dust in spite of careful scrubbing, and I was glad to sit at home in clean and peaceful surroundings.

The next day I continued with my bearing brackets, but as time went on and I had to set up other castings for machining, I found that my neighbours were not so ready to supply me with bolts and clamps. I suggested to Jim Record that if he gave me a requisition for some bolts, I could machine them and make them suitable for use on the table. He would not hear of it. This was my first lesson in self-reliance. I just had to find, borrow or pick up the equipment I needed.

The man on the other side of the gangway working a similar machine to mine was called Jack. I never knew his other name. He did not wear overalls but arrived for work in a three piece suit. The fronts of his trousers, from thigh to shin, were glazed with black grease. His jacket, which he wore with the cuffs turned back, was in a similar condition and tied in the front with string. His hat was a trilby pinched at the front and just as black and glazed as his trousers. He always kept his hat on, which was really very sensible as the men working on the gallery above sent down a constant shower of dirt through the gaps between the boards. He was a lively character and would often burst into song, roaring out “Oh, Mr Porter, what shall I do” at the top of his voice while beating time with a piece of wood. The sound was all but drowned by the roar of the machinery so no one objected.

Among the jobs I had to do was to machine a face on a steel casting called a “Wafer Tong”. It was part of a hinge used with the plates of a flat wafer making machine. All I had to do was to clamp the piece in a vice on the table and set a facing cutter running along the length of the casting. Cast steel was very difficult to machine with a smooth surface and the cuttings came off as chips. These chips were very hot and would burn the skin on you hand if they landed on it. Now I have no doubt that the experience of milling one or two of these wafer tongs would have been instructive, but Charlie the labourer would bring endless heaps of these wretched things and neatly stack them beside my machine. This would go on day after day but it was useless to complain. This was just part of character training, or something.

Part Four

I am sure that it was felt that we apprentices were not destined to become millers or turners. We should disappear after a while into the haven of ease and plenty, the offices; so what was the point of teaching us anything. Charlie the labourer was a cockney who stood about four feet nine, a victim of malnutrition. All his clothes were second-hand. His flat cap was too large and the jacket he wore hung down below his knees like a short overcoat. His shirt had no collar and was held together at the neck with a brass collar stud, while his trousers were belted with a piece of rope. Like all cockneys he was quick-witted and cheerful. He swept the floor, fetched the tea and was on call for everyone on the section. The tea break was one of the bright spots of the day. Charlie came round with a dirty wooden tray to collect up the enamelled mugs and cans. Some men had blue enamelled tapered tea cans with a lid which formed a cup but most had pint mugs like mine.

One day, a very large casting arrived at my machine and in order to get it on to the table, under the cutter, it was necessary to wind the table down as low as it would go. Now, I have explained that this was a very old and worn machine, so that as I wound the handle to lower the table, it came to areas of the slide which were almost new. It became stiffer and stiffer until I could get it down no more. I stood back and stared at it in despair. Now luckily, further up the section there was an apprentice older than me who “had seen the light” and was very religious. A characteristic uncommon among apprentices. When he saw my difficulty, he came forward and lent a helping hand. He turned and turned the handle of my machine and managed to get it down just low enough but it was a tremendous effort. The next day he was away with a bad back. Poor Jack Thompson, he was always doing good works. He had been born on a narrow boat on the canal but had done very well at school in spite of all his disadvantages. He was always cheerful and finally was called to be a missionary in Africa. I believe he died out there of fever.

Now, when I had at last machined this great casting, I had to enlist Charlie’s help in returning it to the View Room, as the Inspection Department was called. What I wanted was a sack barrow; but how should I explain this to him? I knew he would call it a “barra”, but should I ask him for a “barra”. I decided that even if he knew no better, I should use the proper name. When I asked Charlie to fetch a sack barrow he looked at me blankly until the realisation spread across his face. !You want a ‘sack barra’” he said, and went off dancing up the section to tell everyone that this funny creature up the end was asking for a “barrow”. I was obviously putting it on. I should be called Algernon or Archie or Monty or some such highfalutin’ name. It was Monty that stuck and for the rest of my apprenticeship I was called by no other name. I still send Christmas cards signed Monty to friends who date back to that era.

--- --- ---The hooter would sound for lunch time and after wiping my hands on a piece of cotton waste I trooped out with the others into the factory yard. The Grand Union Canal formed the southern boundary of the site and the bank was a favourite promenade at lunchtime. It ran close behind the main factory buildings before coming to an unloading quay where the buildings were set back from the bank. Past the boiler house, the packing department, the carpenters’ shop and finally the pattern makers. This was a strip of shed-like buildings extending almost to the railway line on the eastern boundary. Up at this end of the site the canal branched into a short dead end section for mooring barges out of the main stream. This piece was always referred to as “The Cut”. On fine days we used to take our lunch and sit for a brief hour on the bank throwing stones at tins floating on the dark water. Behind this strip of buildings and extending right up to Hythe Road on the northern boundary, was an area known as “Siberia”. It was certainly desolate and covered with clinkers from the boiler house. Nothing grew there, not even grass. It was used for football either with a ball or a bit of wood, or as a park for vans.

In those days, much of our machinery was sent to customers in our own lorries and on the return journey they would bring back the empty packing cases. These were stacked for re-use at the eastern end of Siberia and formed three or four long lines piled about ten feet high with gangways between. Some were strong boxes but others were rickety with nails sticking out like sharks’ teeth. They were irresistible to the apprentices. We used to climb to the top and jump from box to box trying to travel from one end of a stack to the other. The boxes swayed and sometimes collapsed and there were certain gaps in the lines which needed a prodigious leap. It was all very dangerous and the “Management” stopped the practice from time to time. But who could resist such a challenge and the bad habit would start up all over again.

One day when walking along the canal bank, we found a barge moored out in the middle of the stream near the Cut. The barge had a corrugated iron but mounted on it and four men, working for the canal company, were moving in and out preparing their lunch. Someone threw a piece of coke and it landed on the roof of the hut with a great clatter. One of the men shouted but he was moored in open water so there was nothing he could do about it. We immediately saw the possibilities of this escapade and, crouching down behind a pile of rubbish so that we could not be individually identified, we proceeded to pelt the iron hut with coke and stones. The poor workmen could not get away for protection. The noise of the bombardment must have been devastating. When we tired of the game, we slipped away and walked back to the factory. We heard later that a very angry workman had called at the factory gate demanding to see the works manager. However, as he was unable to say who the culprits were, and he was only a labourer anyway, he was sent away. That was considered a very satisfactory prank. An adventure of this kind enlivened the long working days.

--- --- ---Sometimes I would take a walk through the other sections of the factory and stare at the tinning vat full of molten tin. Then down to the coppersmiths to watch two men beating out a great jam pan under a mechanical hammer. Turning the discs of copper round and round over a stake until the final domed shape appeared. Next the blacksmiths section to watch a smith and his striker working as one. The hot iron was turned this way and that before it cooled and had to be returned to the fire. I was not supposed to leave my machine so these excursions had to be brief.

We had no paint shop as in a modern factory, but only a store for materials. The painters moved about the factory, painting work as it proceeded from section to section for different machining operations. Our favourite painter was Tom. A great tall man with only one eye. It was said that at one time he had been a cowboy and he did nothing to contradict the story. He walked like our heroes of the cinema and told amazing yarns of foreign places. Tom squat on a little box and paint the base of a melangeur; a big heavy casting. First the grey filler would go on and be rubbed down with sandpaper. Next the matt chocolate coloured under-coat and finally several coats of varnish. It was all done with a brush, and the final finish when hard and dry would last almost the life of the machine. Often I slipped away to chat to Tom and encouraged him to tell some tale of rounding up cattle in far away places. I would then return to my machine and imagine myself riding the range which seemed infinitely more attractive than this noisy, dirty, factory.

Sometimes the belt on your machine would break and it would be necessary to fetch “Belty”. He was to be found in the middle of the factory, surrounded by rolls of belting and tins of Black Jack. He was so dirty, sitting far back in his den, that you first discovered he was there by the whites of his eyes. He would come and cut out the worn piece of belting, hammer in a new Alligator fastening and add a new piece of leather. It gave one a chance to lean back at ease without having to pretend to be busy. Of course, the great occasion was when the main belt broke. The peace was heavenly and the whole section stopped. Then Belty was really busy. He used screw clamps to bring the ends of the great twelve inch belt together and judged the length of the new piece required to give the precise tension. The interval was short and the great motor would soon be humming again.

--- --- ---One day, quite unexpectedly, Mr Boreham told me that my nine months’ experience on the milling section was at an end and I was to report to Alf Flaxman, the charge hand of the turners. Alf was a little man in a flat cap who wore a brown warehouseman’s coat, which seemed to be the chargehand’s uniform. He was not too bright and I soon found he could be blinded with science. He took me to a centre lathe in the middle of the factory, under another wooden gallery. On my left were other lathes and to the right the turret section. I was lucky to be on a centre lathe as most of the apprentices were assigned to the turrets. These were automatic machines on which repetitive items were made. Pins and rollers for chains, sleeves and collars. It was boring and not so varied as centre lathe work. He explained the machine to me and I soon discovered that this was also very old. It had lost its capability to cut screw threads and was confined to plain turning. When it was finally set up, if left to itself with the work between the centres, it would turn a tapered shaft. To correct this I used to keep a heavy billet of steel with which to clout the tail stock, and became expert in applying just the right weight of blow to make the lathe run true.

I used to turn small shafts and bushes, working to the blue prints made originally by George Jordan and pasted on to thick cards. I quite enjoyed this job and learned to grind my cutting tools on the section grindstone. One day I found by careful grinding and setting of the tool, I could get a very high polish on my bushes. In fact, the finish was so bright and looked so beautiful that I avoided fingering the surface. Next day Alf came along with a man from the View Room to tell me that all my lovely bushes were scrapped. In attempting to obtain my “super gloss” I had burnished the bushes with the point of the tool instead of cutting them. The result had been that the work had become very hot and though, in this state they were acceptable to the gap gauge, when they cooled they shrank and were useless.

It was about this time that I first met Ron Edgar, a nephew of Josh Booth, the works manager at Peterborough. He was younger than me and had a very sallow complexion. He never looked clean and to top it all he had a mop of black curly hair. The workmen christened him Sambo and it was years before he was again called by his proper name. Now Sambo was very resourceful, which later made him a very useful outdoor engineer. I remember that he once turned up a shaft having two diameters on it. Unfortunately he misread his rule and turned the smaller diameter about an inch too far up the shaft. It was a pity, because all the rest of it was correct. To solve the problem, Sambo turned up a collar, went to see the blacksmith, heated it and shrank it into place on his shaft. He set the work up again in his lathe and turned it exactly to size and length. So good was the repair that no one would have spotted it. Sambo proudly took his shaft to the View Room and told them what he had done. He never could understand why they scrapped it.

--- --- ---On the turrets to my right there was a group of apprentices who enlivened their repetitive jobs with practical jokes and ribald ditties. Smearing black grease on a neighbour’s hand levers, to cause him embarrassment as soon as he went to start his machine, was a common trick. Anything to relieve the monotony of turning the big star wheel levers, to wind the tool into the work rotating in the chuck. Then wind it back, for the turret to rotate and bring the next tool into operation. The ring leader of this little gang was Ginger Wil-de-Gosse. An unhealthy looking soul. He had that pale complexion and white pimply skin that goes with ginger hair. Now, one day Ginger was making chain bushes; feeding the drill forward to drill up the centre. Having started the drill, he locked the machine into automatic and the star levers turned steadily, feeding the drill into the work. Just at that moment he saw something which had dropped into the swarf tray beneath his machine and bent forward to retrieve it. As he did so, one of the levers of the turning star wheel caught in the front of his shirt and dragged him down into the swarf tray. When he realised what was happening, he took fright and wrenched himself free. He stood up, somewhat shaken, to disclose that the lever had ripped off one sleeve and half his shirt. The other lads howled with delight and all sorts of suggestive remarks were made about his new style of dress and his lily white skin. They were a cruel lot.

--- --- ---On another occasion, the turret gang, when wandering beside the canal path one lunch time, came upon Ginger sitting on top of a large crate reading a copy of Picturegoer. It was a lovely sunny day and he was disturbing no-one. One of the group just leant against this tall box and it was seen to sway slightly. Now, this tall perch was standing right on the edge of the canal bank, a fact which had attracted Ginger to climb up and enjoy the view. However, as soon as it was discovered that the box was unstable, it immediately suggested all sorts of wicked ideas. Perhaps they could scare him. Another lad gave the crate a push and it swayed a bit more. Ginger swore and clung to his perch like a cat, but once they had worked up a good rhythm there was no stopping them. Poor Ginger swung from side to side and, of course, finally pitched off the top into the water. Then it was all hands to save the drowning. The water was not deep. In fact, there was no more than three feet of water and a lot of mud. The poor chap was pulled ashore, spluttering and cursing, to the great delight of the crowd. The mud was scraped from his boots and trousers and he went to dry off in the boiler house. It was a long time before Ginger was allowed to forget the incident and he was careful never to give them another chance.

Part Five

About this time, we were starting to build the biscuit stacking machine and I believe there was some discussion as to the best method of manufacturing the paddle wheel. Vicars, our deadly rival, made their paddle wheels with a series of plates shaped like the “Legs of Man” separated by spacers. The paddle wheel had to be this shape to allow the comb plate to receive the biscuits as they were lowered on to it. The original Baker Perkins idea had been to cut the unit from a solid bar but there was some doubt about the cost of this method of manufacture. I was told that Mr Ralph Baker decided to time the turner who was cutting the gaps in the bar before the formation of the legs. The story, as I heard it, was that he stood out of sight and timed the operation with his watch. If this were true, such an operation would be fatal.

To imagine that anything could take place in the Works without it being seen, was quite impossible. The grapevine would certainly have advised the operator to keep his speed down, so that the test would not have been accurate. Eyes were everywhere in the Works. One day, when some lade were waiting for tools at the tool store, one of the little messenger girls climbed the steep stairs to the office where Cyril Ballenger worked. Unfortunately, these stairs were very close to the counter of the store and some rude youth looked up and announced for all to hear that “she has got her blue ones on today”. Evidently, the poor child returned to her office crying with embarrassment and the incident was reported to Mrs Gabitas. Now Mrs G, as she was called, was the Personnel Department. Anything of a social nature was reported to her and she would deal with it. Whether it was a misdemeanour, or a domestic problem, either in the Works or with the staff. She was very competent and her word was law. Not that this was her only job, she was really confidential secretary to Mr Kirman and Mr Gilpin, managers in the commercial office. A directive was sent down to the Works that in future it was to be “eyes down” at the tool store counter and any repetition of this behaviour would be severely dealt with.

One of the first jobs for a girl coming from school at the age of fourteen, was to carry papers between the various departments. This, of course, meant that she sometimes had to walk through the factory. To some of the girls this was a terrible ordeal. The poor child would walk down the dead centre of each gangway not daring to look to right or left, ready for instant flight. Her progress would, of course, be watched by all the young bloods and every detail of her dress and manner noted. It must have been a great relief when she finally reached the factory door and could escape out into the yard. When she had gone past, a turner on a lathe near mine would hoist a great billet of steel above his head and let out a roar like a bull elephant. This was to advertise his carnal desires and his undoubted virility! It was indeed a great feat. All the apprentices tried to lift up that great lump of steel but it was too heavy. All I could do was to lift it waist-high, using both hands. He was certainly virile.

--- --- ---Another piece of equipment for which my foreman, Alf Flaxman, was responsible was the oil grooving machine. He had a northern accent and persisted in referring to it as the "Iol grooving machine”. He never did understand how it worked and left one apprentice to show the next how to operate it. It was really a converted lathe, which had been fitted with an adjustable crank and a lever, connected to the tool carriage. When connected to the tool carriage. When the lathe made one revolution, the carriage moved to the right and back again to its original position. The shaft to be grooved was put into the chuck and the stroke of the crank adjusted to give the required length of groove. After cutting one oval groove, the shaft was turned through 90º in the chuck and the second path cut, crossing the first at the point where the grease hole had been drilled. It was really all very simple, but poor Alf never did master it. I had several spells on this machine. The tool was most unusual, as it virtually had to cut in all directions. The tip was diamond shaped and scraped the groove, rather than cutting it. This friction tended to turn the shaft in the chuck, unless it was very securely tightened, and if this happened, a most amazing pattern of grooves would appear all over the shaft. The practice was then to call Alf over to the machine and explain that “the eccentricity of the rotation had become disassociated from the longitudinal displacement” or some such rubbish, and poor Alf would go off to the View Room to explain why this unfortunate shaft was scrapped. We never got a lecture for it, and if he decided to put another apprentice on the machine, so much the better. It was a boring job.

Alf had a son who had originally started in the Works as a turner, to follow his father in the traditional way, but the lad had other ideas. He joined a jazz band, a terribly decadent occupation in Alf’s eyes, but when the son was earning more money than his father, Alf was convinced that times were not what they were.

One day, a speck of metal flew up from my machine and lodged in my eye. Tears ran down my face, but nothing would shift it. I went to one of the St John’s Ambulance men, who provided first aid for the factory, to see if he could help. He took me to the light and rolled my eyelid back over a match stick. The piece of hot metal had stuck to the eyeball and would not move. “We don’t like poking about in eyes” he said, “You had better go to Moorfields”. This was the London hospital specialising in the treatment of eyes. I set off just as I was and walked to the Harrow Road. Here I caught a tram and found my way to the Out Patients’ Department. There were many other men there, mostly factory workers with similar trouble to mine. We sat in rows on forms and moved forward as those in front were treated. When it came to my turn, a nurse rattled a collecting box in front of me and said “How much can you afford to pay?” Now, this was difficult, for if my sight were in danger, then no price was too high, but if it were a simple job- before I could decide this difficult question, “Half-a-crown” she said and fortunately I had enough to cover this in my pocket. I had been so concerned about my eye, that I had not given a thought to what it might cost. The removal of the speck was simple, but I came away with my eye covered and a bandage all over my head. I thought all this a bit unnecessary but at least it showed I had a valid excuse for being away from the factory. It cleared up the next day and I soon forgot about it.

The light in the factory was bad under the galleries and each machine was provided with its own lamp dangling from a flex. Mine had an improvised shade made from a cocoa tin and the bulb was of the original Edison design. It had a single coil carbon filament. It was winter time when I was working on the lathe and life was miserably cold in the factory; especially on Monday mornings. There was no heat in the factory over the weekend and when we arrived at 7.30am the steel handles of the machines were icy. The factory was heated with cylindrical stoves, having cast iron tops and feet, and sheet iron bodies. From the top of each stove, a sheet iron chimney went straight up through the roof. ”Tortoise” was the trademark of these horrors and a labourer with a barrow and a shovel came round stoking them with coke continually. If your machine was close to the stove you roasted, and if you were unlucky and about twenty feet away, you froze. I used to pile on extra clothes under my overalls and wear a scarf, but I was never warm until the afternoon. By then the carbon monoxide from the burning coke had drifted round the factory and by five o’clock we were all a bit drowsy. It was not until the buzzer blew and we escaped into the open air that we realised just how bad the atmosphere had been.

It would be getting dark and if it was raining I would button my old raincoat at the neck and make for the cycle shed by the Works gate. The light from the factory glinted on the wet cobble stones and the rain blew in my face. Shielding a match from the rain, I lit my oil lamps and charged out of the factory gate with the others, for the long pedal home.

There was no time to spare. A quick wash and change, a meal and off to catch a bus to Kilburn for the evening classes. On nights when the subject was mechanical drawing I had to take my little quarter Imperial drawing board and tee square wrapped in brown paper. This was in addition to the case of instruments and books. After the bus ride there was a long walk to the school in Paddington. The instruction was tedious and such notes as I took were fragmentary. By the time I got home again there was time for nothing but supper and bed. This was three times a week and as we had to go to work for half the day on Saturdays there was little time for anything else. However, this was normal, it was what all the apprentices did and we did not feel deprived.

On winter mornings, when I set out for work, it was dark and I would pedal along Lydford and Sidmouth Roads up the long hill, cycling from one patch of yellow light from the street gas lamps to the next. Then as I reached the top, if the morning was fine, I could see the sun rise away in the east. I enjoyed that.

One lunch hour I had been shopping in the Harrow Road and was cycling back to work when a car ran into me. I was not hurt, but the impact buckled my back wheel. It was so badly bent that the wheel would not turn, so I had no choice but to put the cycle on my shoulder and walk back to the factory. Now, this was serious. How was I to get home? There was no cycle shop in the Scrubs Lane area, so what was I to do? I was wailing and asking advice in the factory when an apprentice a year or two older than me suggested that if I could get the bike into the confectionery fitting shop he might be able to repair it. This was a wonderful offer and I lost no time in collecting the machine from the cycle shed. I had to remove it while the man at the gate was not watching and scuttle with it behind the central office block and into the factory. This done, all I could do was wait and hope. At five minutes to five I wandered over to the fitting shop, and sure enough, my bike was ready. Jack Hunt, my saviour explained that two spokes were missing but otherwise it was safe to ride. I was so relieved and thankful that I do not remember whether I handed over the recognised “packet of fags” for a “foreigner” of this nature.

From my position on the lathe I sometimes watched Alf Stower, an old craftsman, from the View Room on his way to straighten a big shaft that had come in for repair. Wearing steel rimmed spectacles and his head stuck out in front, he marched along. A crowbar in one hand and a seven-pound hammer in the other. He would test the shaft on the lathe with a piece of chalk and get a labourer to swing on the crowbar over a piece of wood on the lathe bed. Then he would hammer the shaft, protected with a piece of plate. He knew just how hard to hit and after a few trials, the shaft would be true and as good as new. I used to listen with awe to his tales of the early days. How he had climbed to the roof of the factory and, sitting astride the line shaft, had cut a key way in it with a cross cut chisel and a hammer. “How many men could do that today?” he would ask.

Working on the lathe near me was an apprentice who rejoiced in the name of H.A. Maxwell-White. His father was one of the senior members of Keith Blackman of Tottenham, the firm that supplied the gas equipment for our ovens. Now HAM was a popular lad, eager to have a go at most things. He knew very well that it was dangerous to attempt to change the speed of his lathe without stopping the machine, but he had seen some of the old hands perform this feat with such apparent ease that he decided to have a go. He succeeded in guiding the belt off the pulley of his lathe and after repeated efforts, managed to fling the loose belt on to the selected pulley of the line shaft. All he now had to do was to guide the belt with the flat of his hand on to the corresponding pulley of the lathe. The belt was a bit tight and he could not get it to pick up. He pressed a bit harder and as the friction of his hand against the belt increased, his hand moved closer to the pulley. Then of course he made the fatal mistake and allowed his fingers to curl round the belt. In a flash, his fingers were trapped between the belt and pulley and his arm dragged under the lathe head. He snatched his hand free and remarked “Now all my fingernails will go black”. That was before the pain came. Poor fellow, his hand was in a dreadful state and it was some time before he was back at work. To me, it was a powerful object lesson and I resolved never to risk following his example. I was always afraid of damaging my hands. So many of the men had odd fingers missing through one cause or another.

I was still a member of the scouts, so now I could go off on Friday night for a weekend camp and forget all about the grimy factory. Sambo was also in the scouts. He belonged to a Sea Scout group based on the Thames. I suppose that it was this that inspired him to build a boat. He told me that when it was completed, he persuaded his local greengrocer to take it on his cart to the nearest point on the river. When he arrived, there was not a soul about, but by the time he was ready for the launch, quite a crowd had gathered to see him set sail. Now, the boat was very small, a cross between a canoe and a rowing boat, and as he pushed off from the shore he realised that there was very little free board. However, there was no turning back. The water started lapping over the side and he was soon getting very wet. He paddled hard towards a clump of trees, just out of sight of the onlookers and beached his craft as soon as he could before it sank. I think he left it there. In any case, I have never heard him refer to it again.

--- --- ---/MHP 20.3.08

All content © the Website Authors unless stated otherwise.